The Problem

Techniques in managing Supply Chain Compliance have remained stagnant for decades.

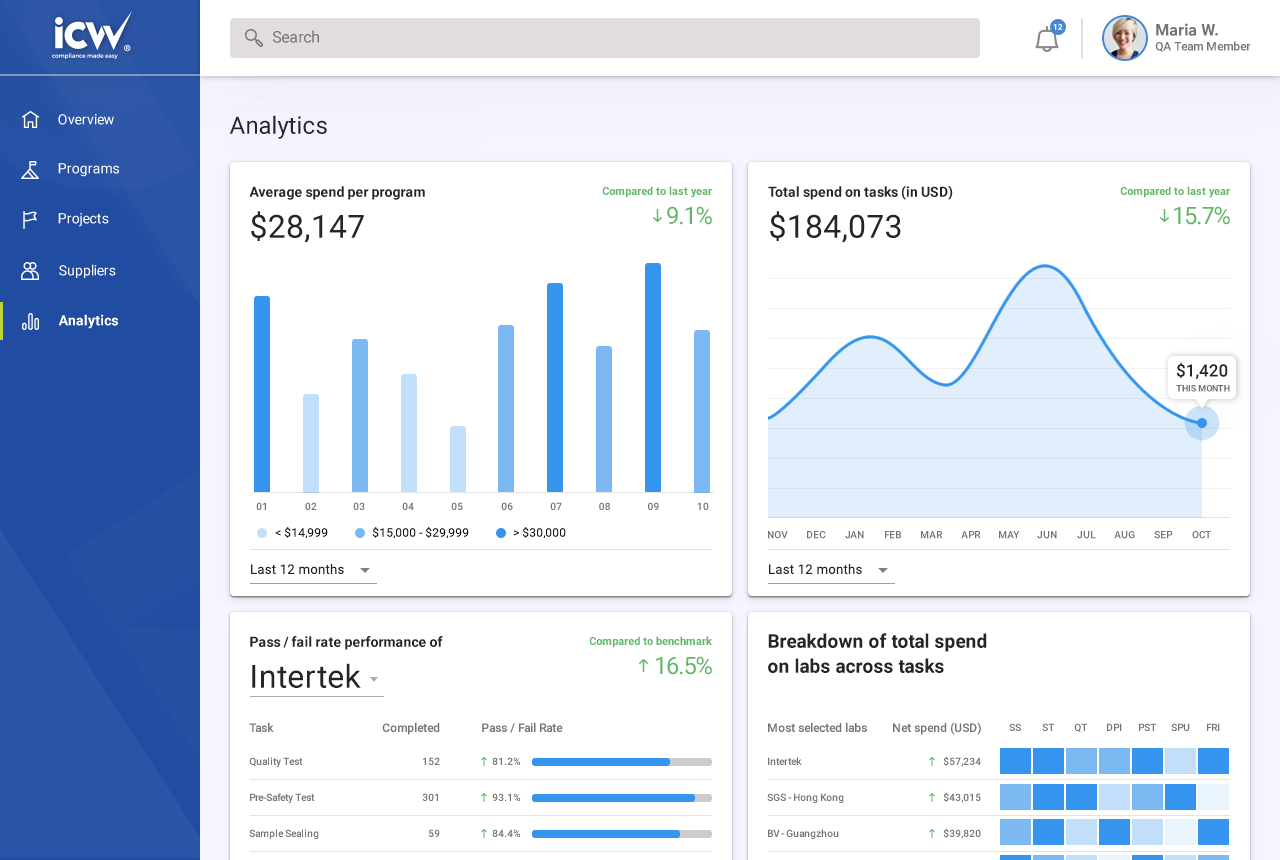

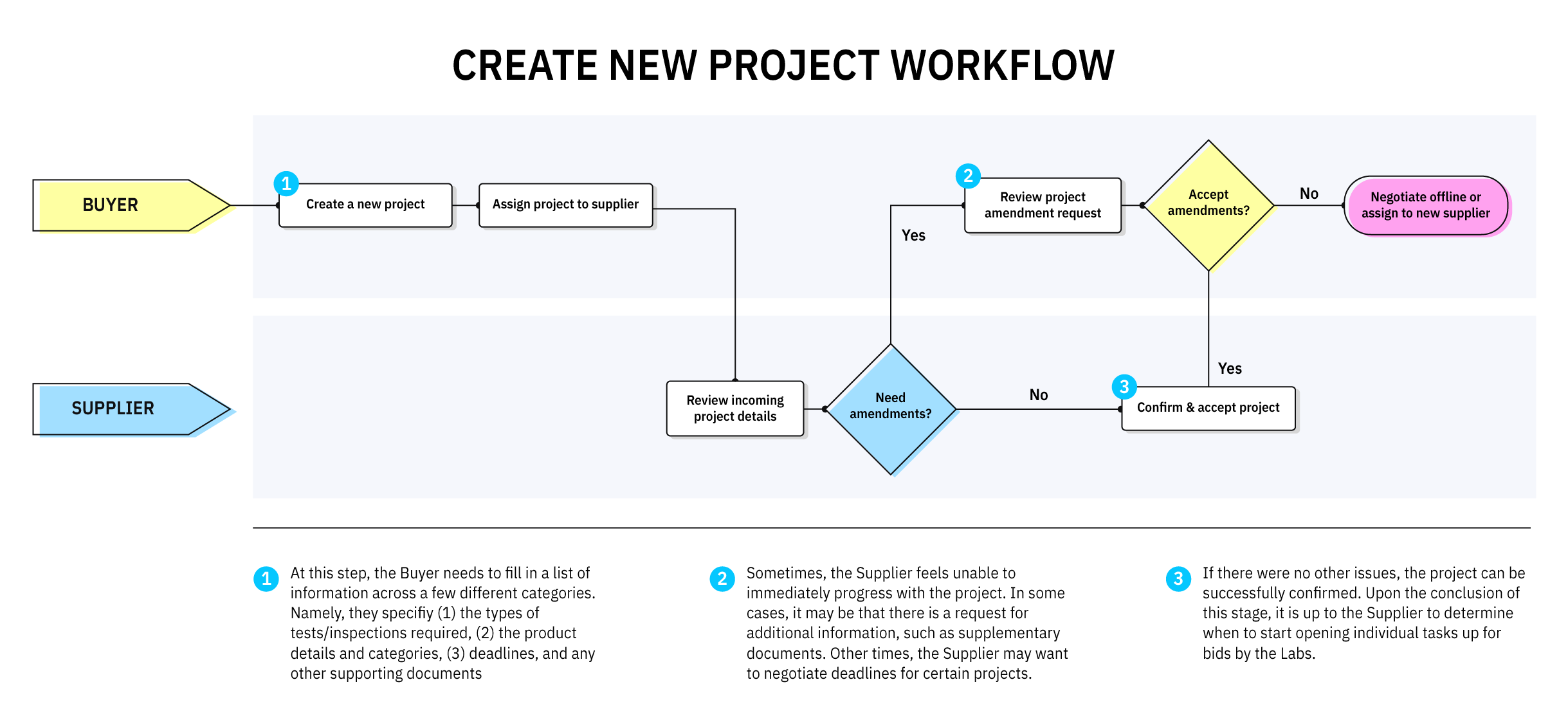

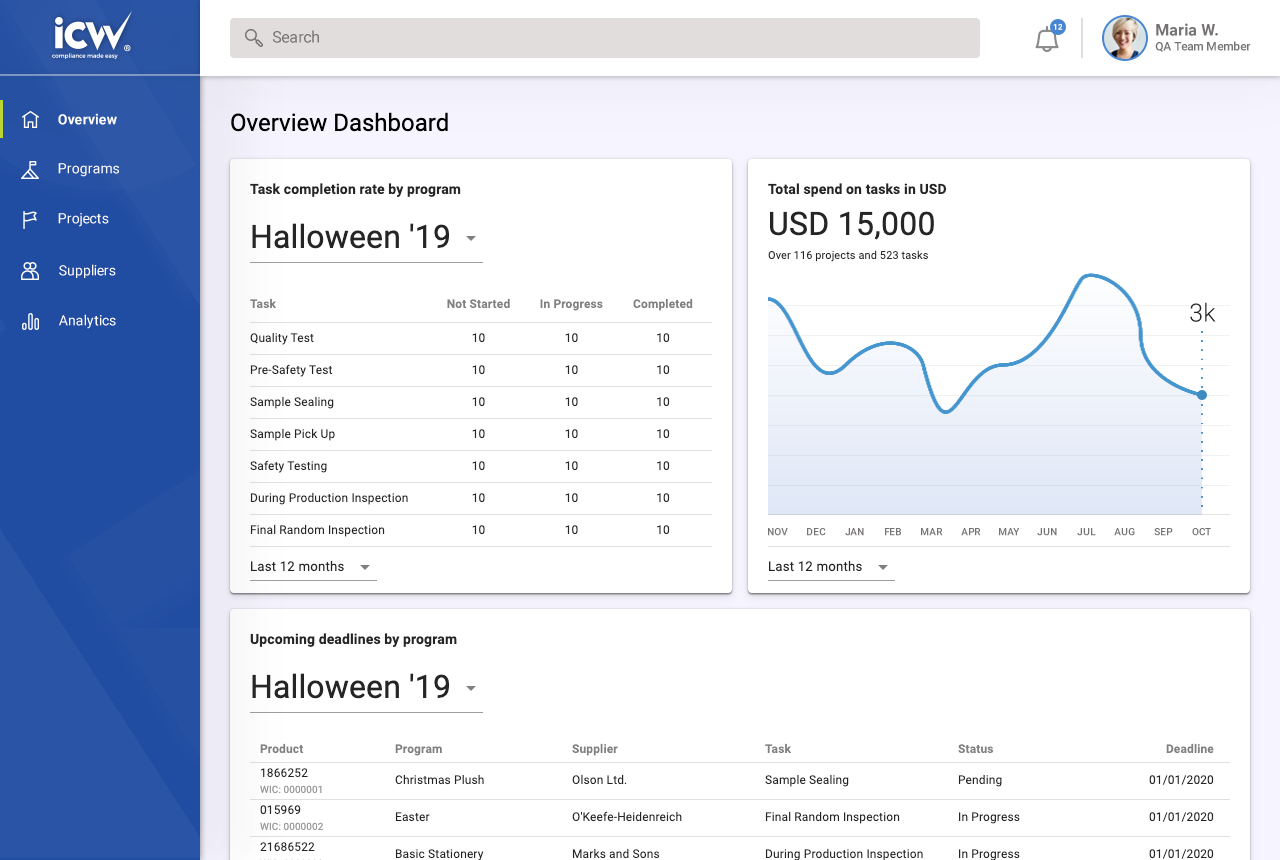

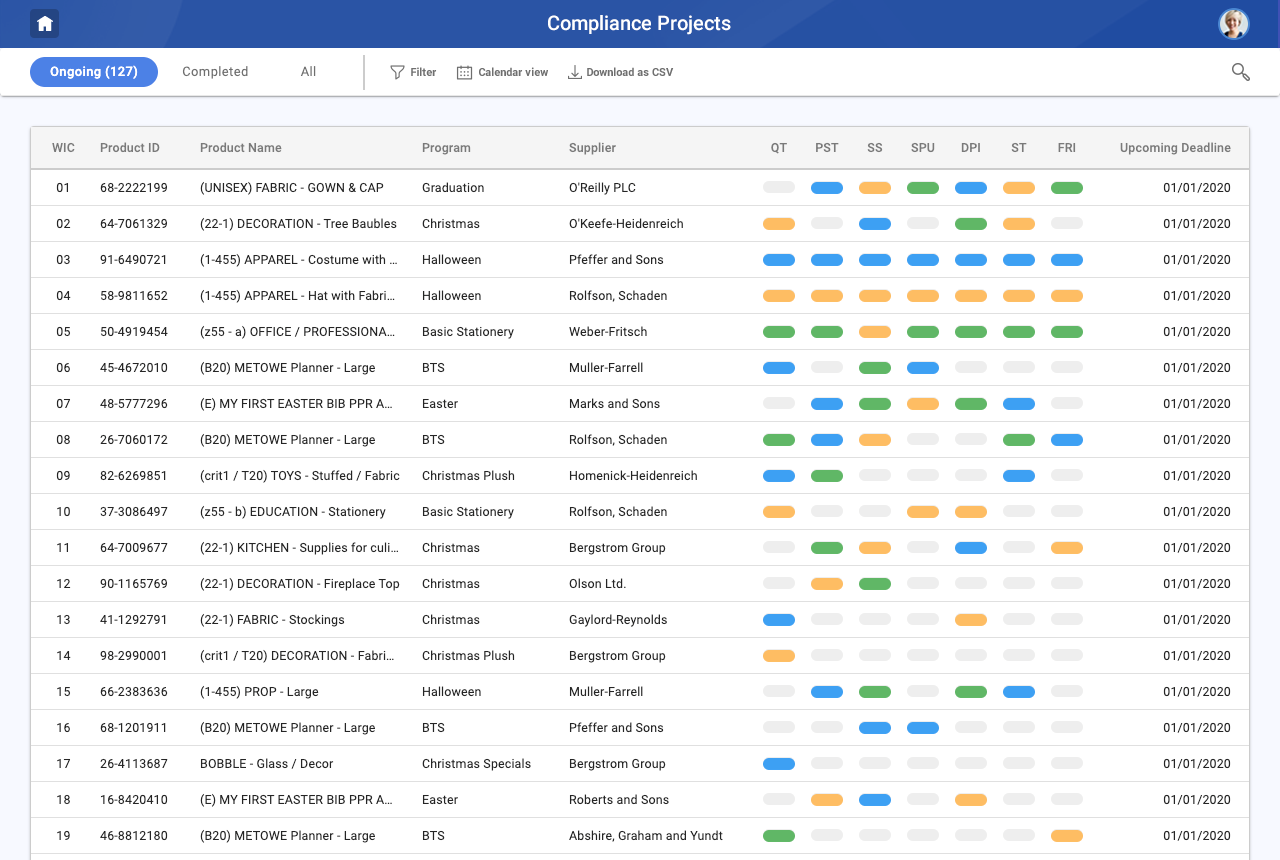

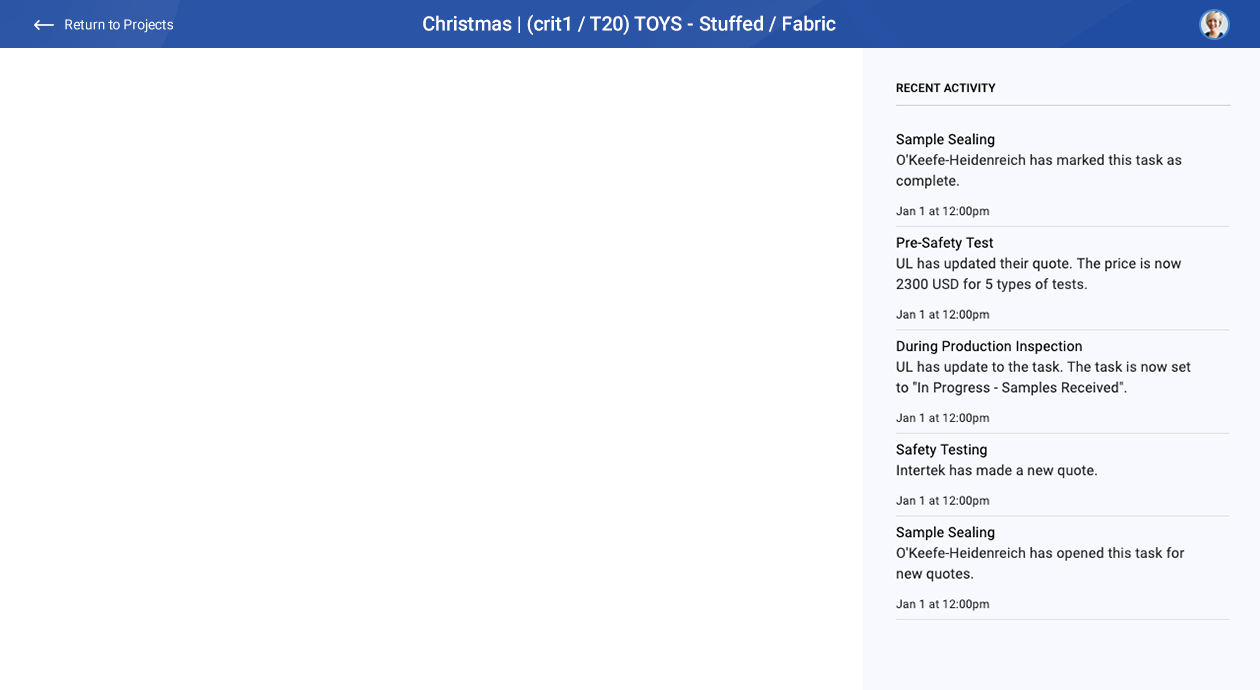

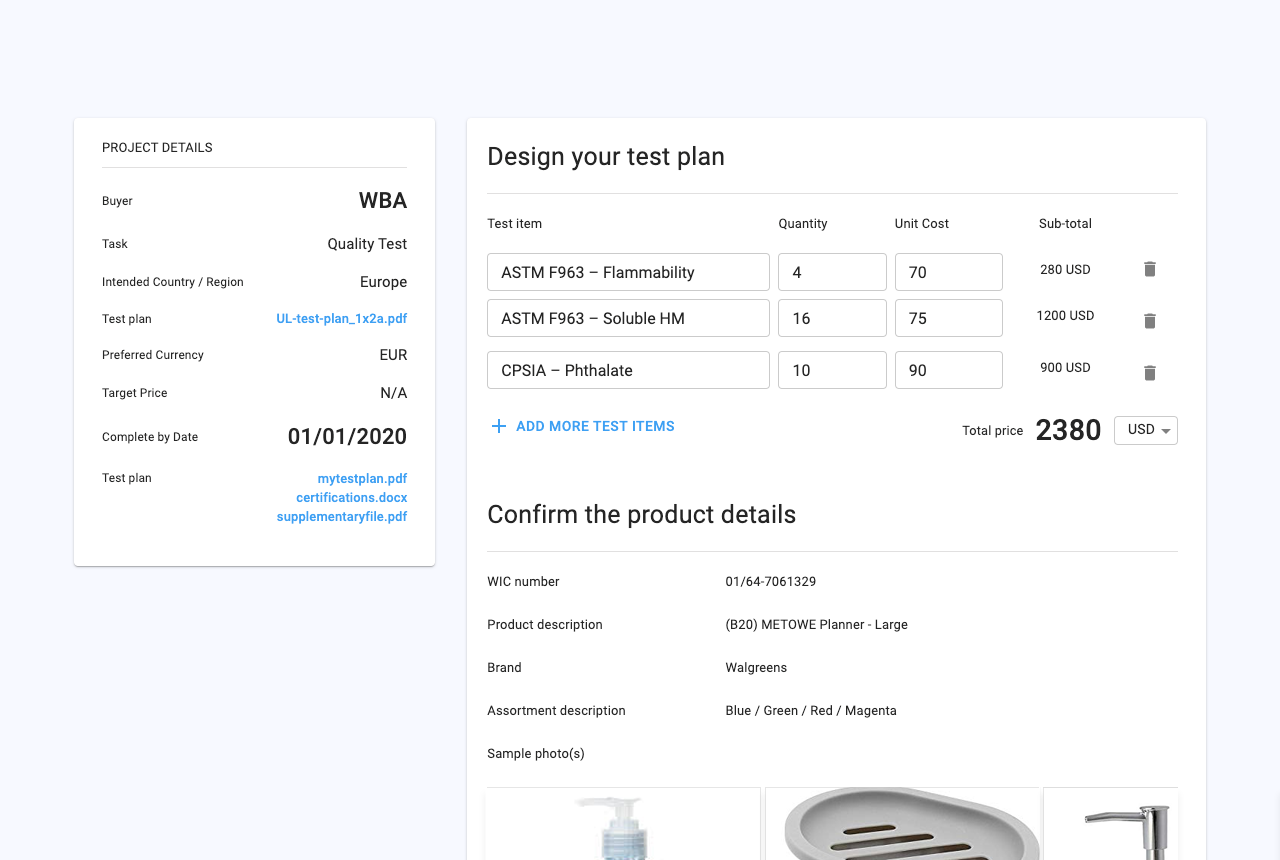

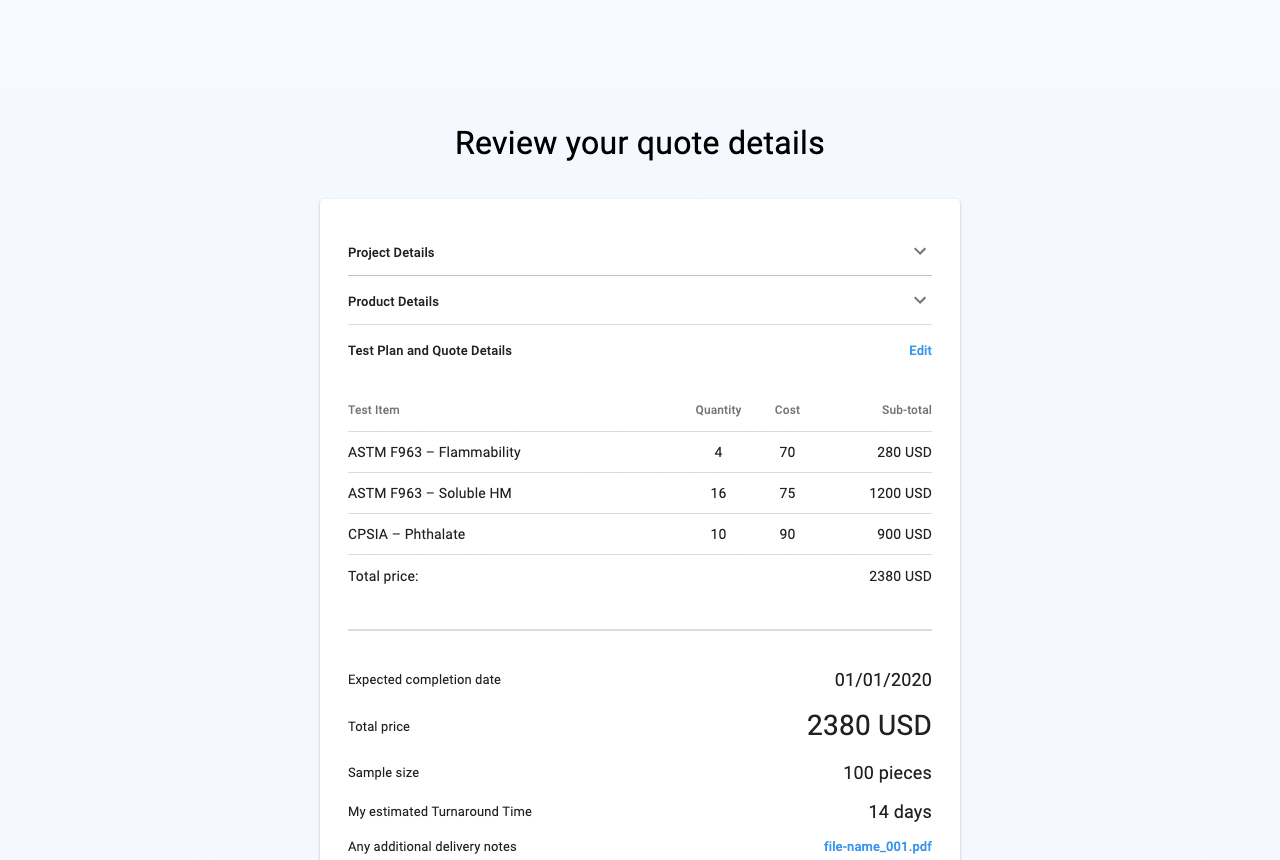

Every season, WBA have to ensure their catalog of 1000+ products pass Quality Assurance / Quality Control tests before they can be shipped out. To do so, they coordinate with 100+ suppliers to delegate portions of their catalog.

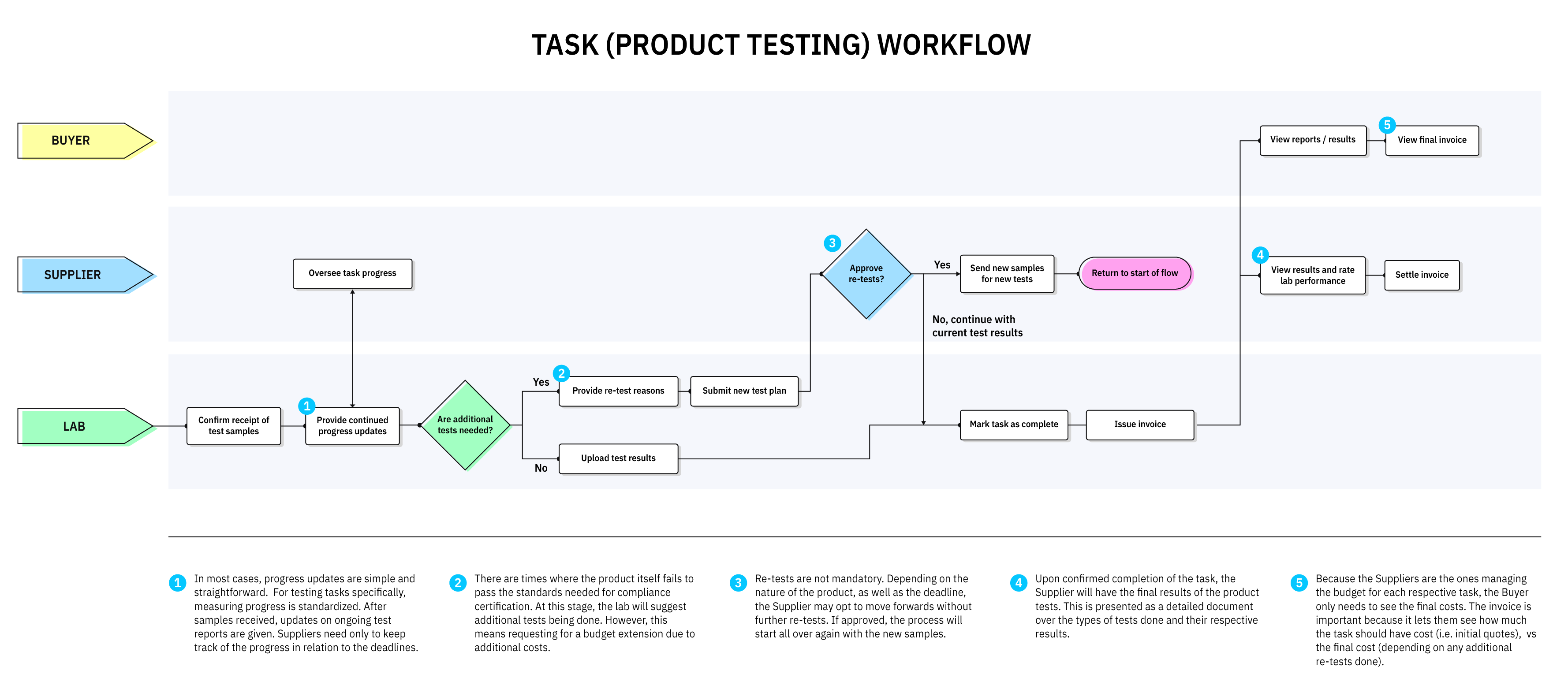

During this process, QA / QC teams still rely on phone calls, emails, and spreadsheets for their work. Something as simple as following up on project progress means manually calling each one of their 100+ of suppliers. Important documents are difficult to keep track of due to fragmented workflows. Budgets grow out of control due to sudden need for additional tests. The list goes on.

As modern compliance becomes more complex in scope and scale, the traditional technology that QA / QC teams use fail to keep up.

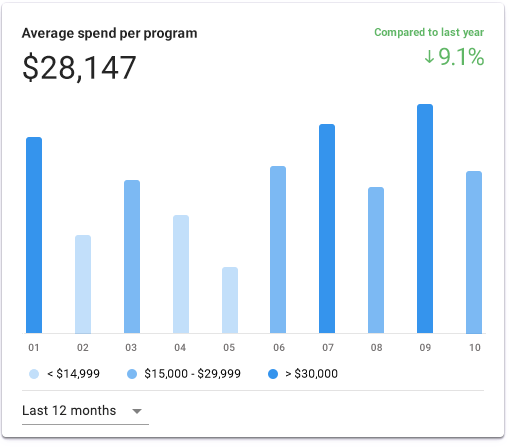

10

Weeks spent manually collecting the purchase order of a season32%

of the QA team's time is lost to chasing up on project progress3/5

Seasons go overbudget without clear reasons as to why